Services

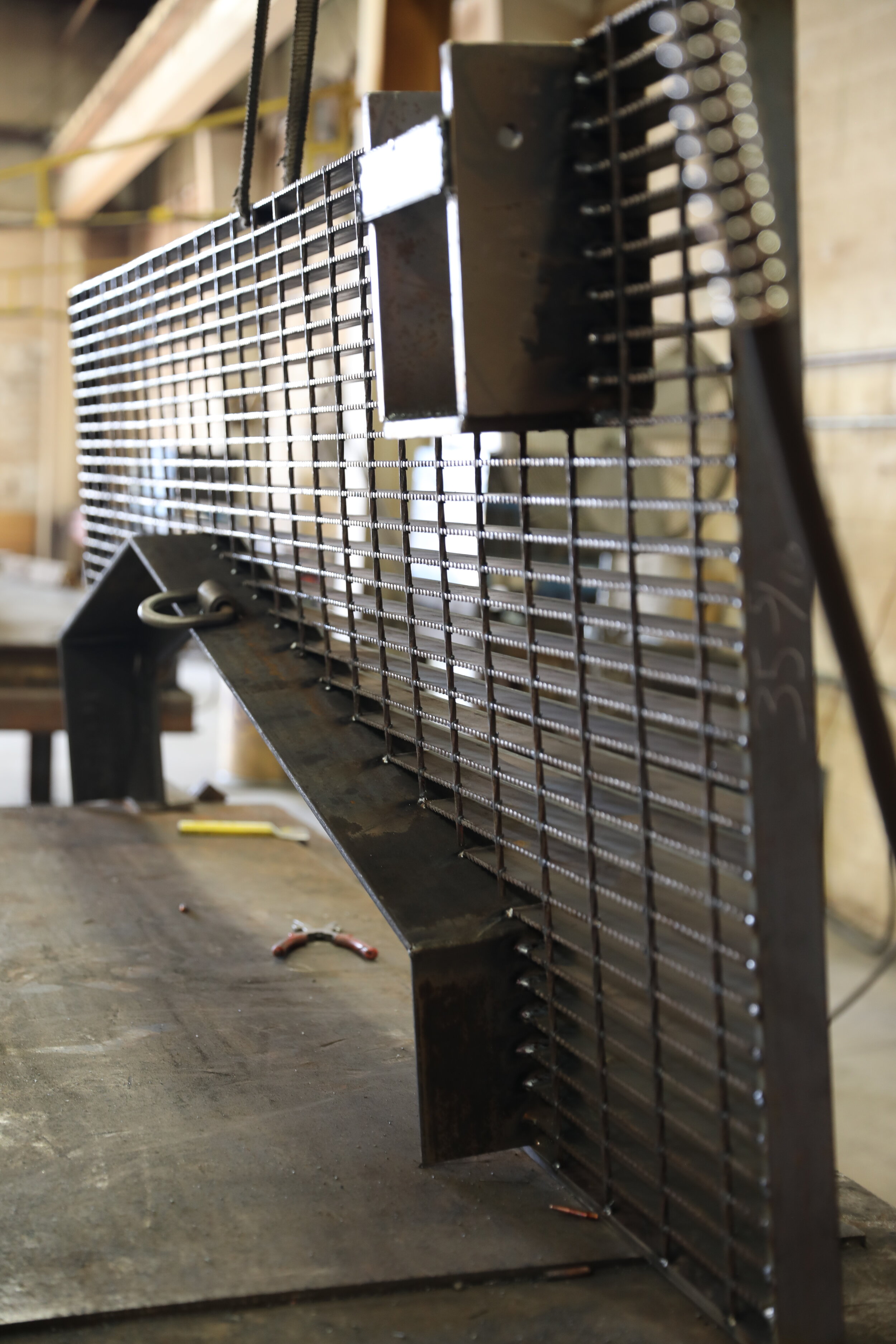

Heavy Fabrication/Welding

What sets MMW apart from the rest is our capability to move, fabricate, weld, and machine heavy material. Our facilities have numerous overhead cranes (up to 10 ton capacity) and high capacity forklifts (up to 35,000 lbs) that give us the ability to handle large jobs. The heartbeat of MMW is our many talented and dedicated welder/fabricators certified to AWS D1.1 and D14.1.

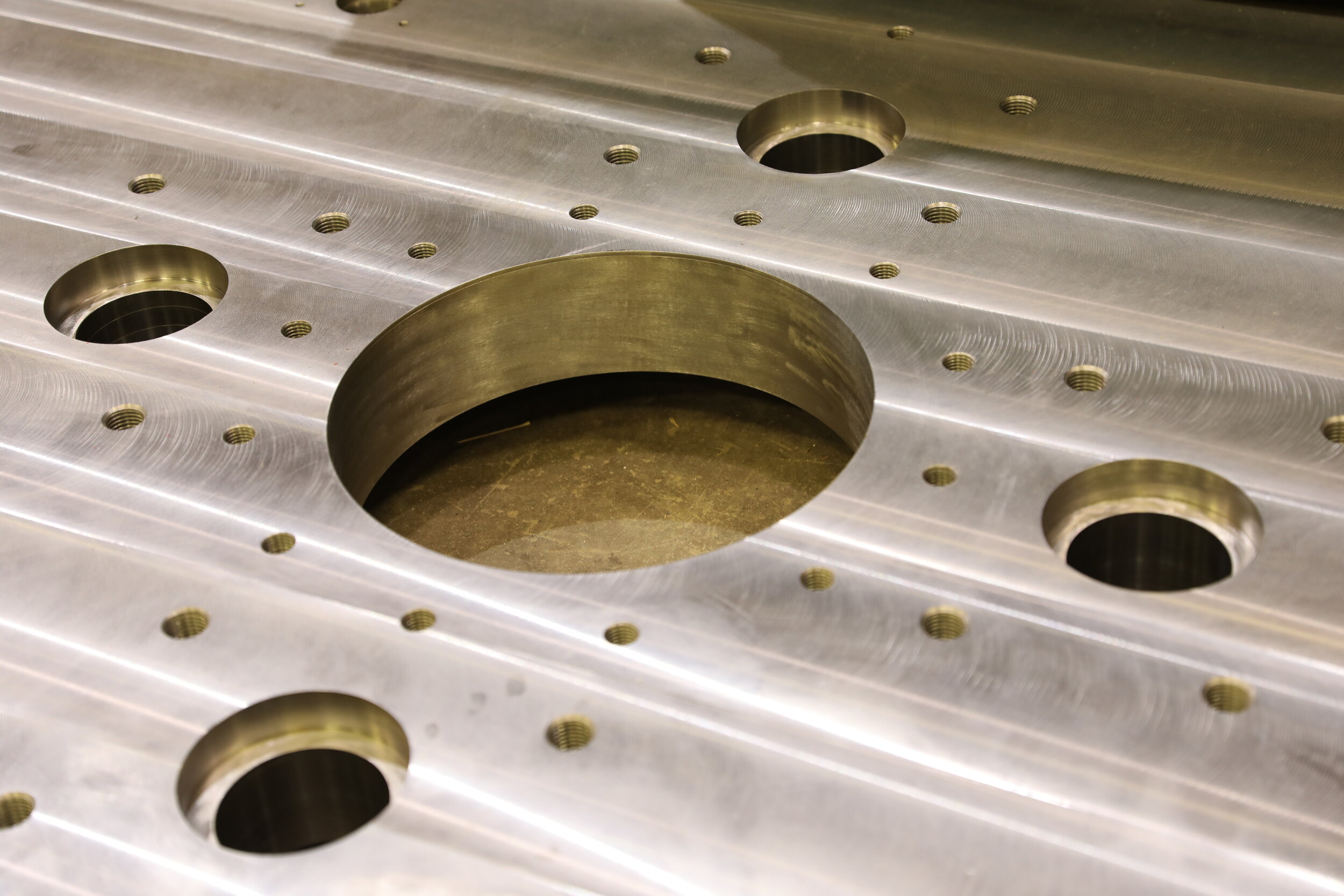

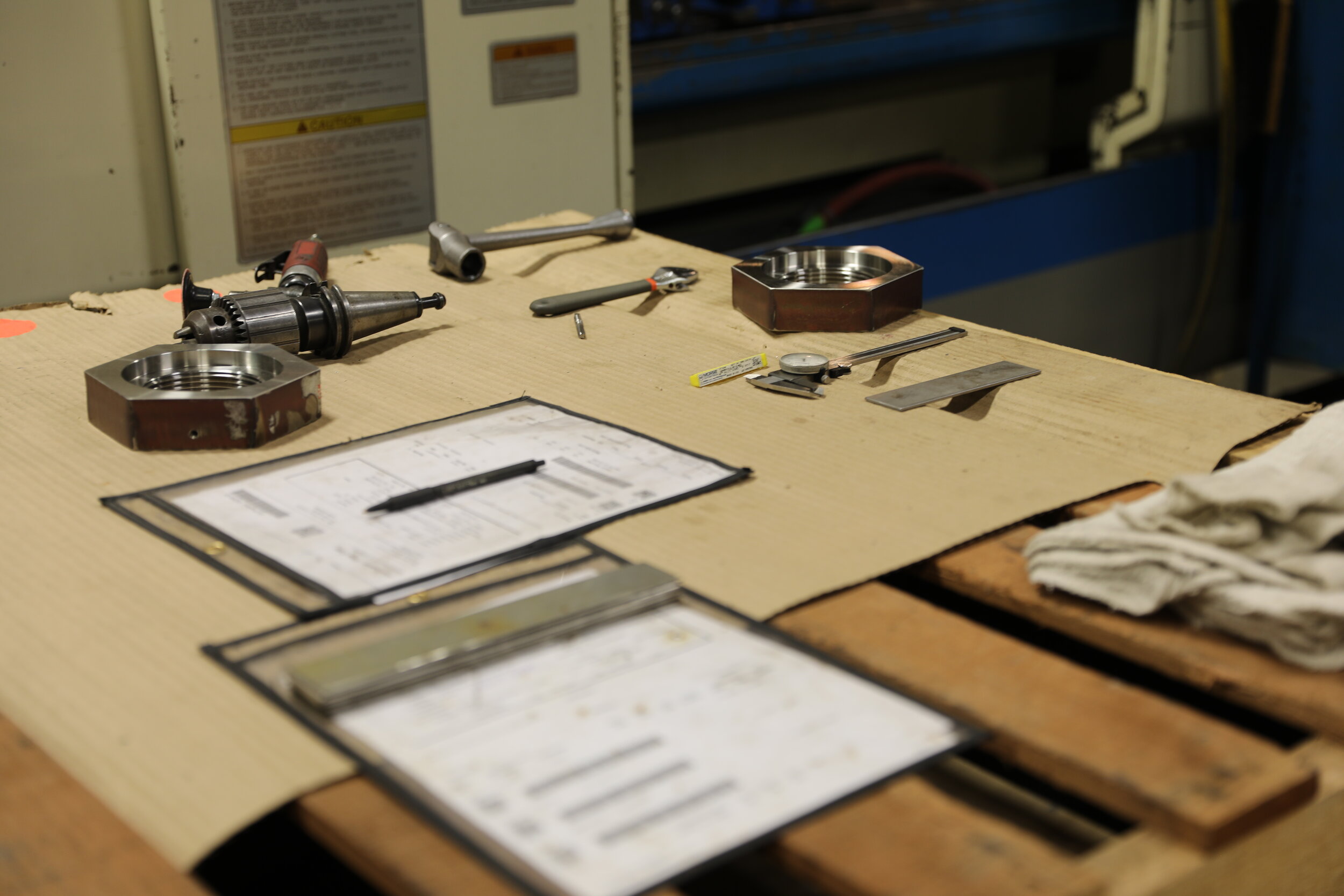

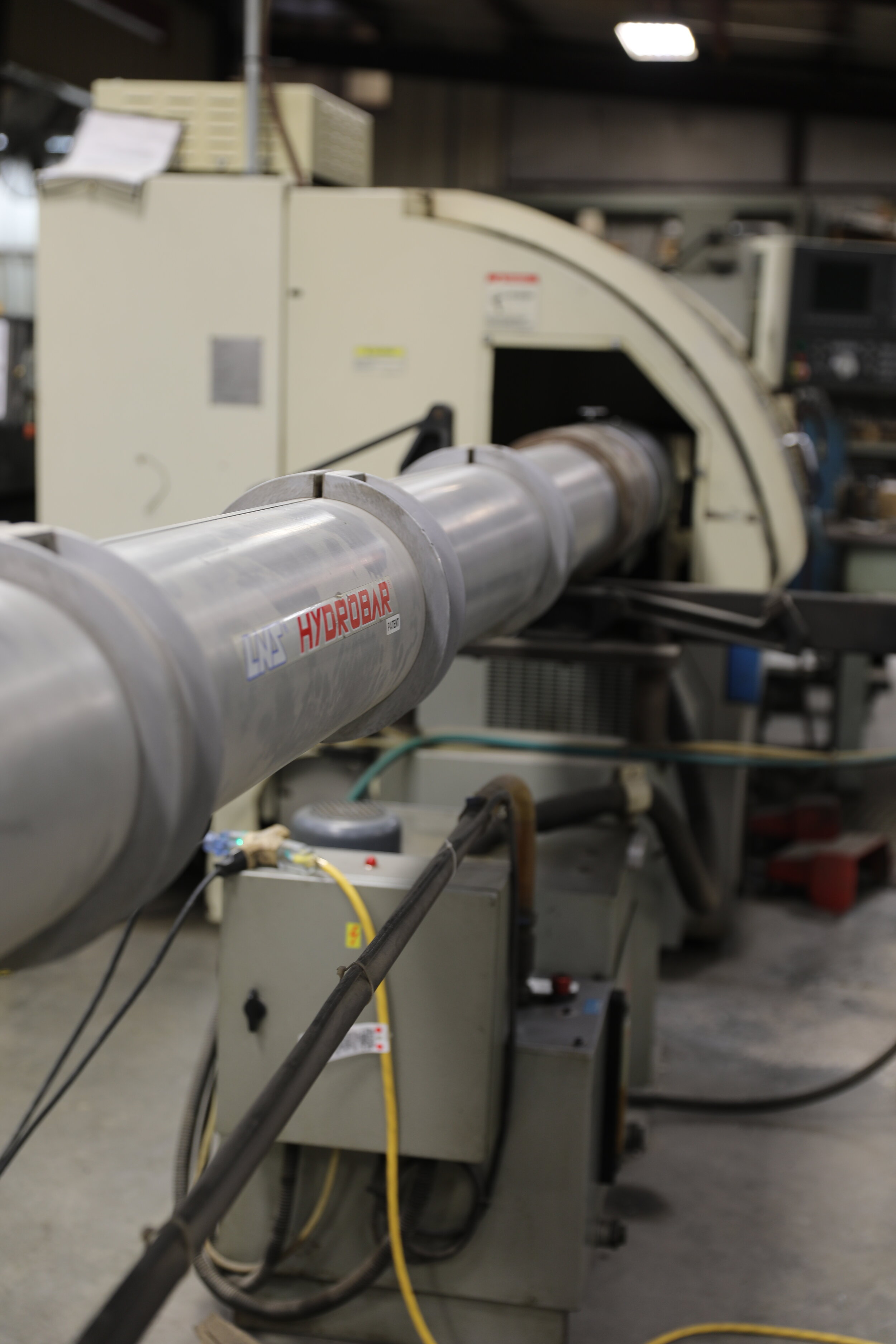

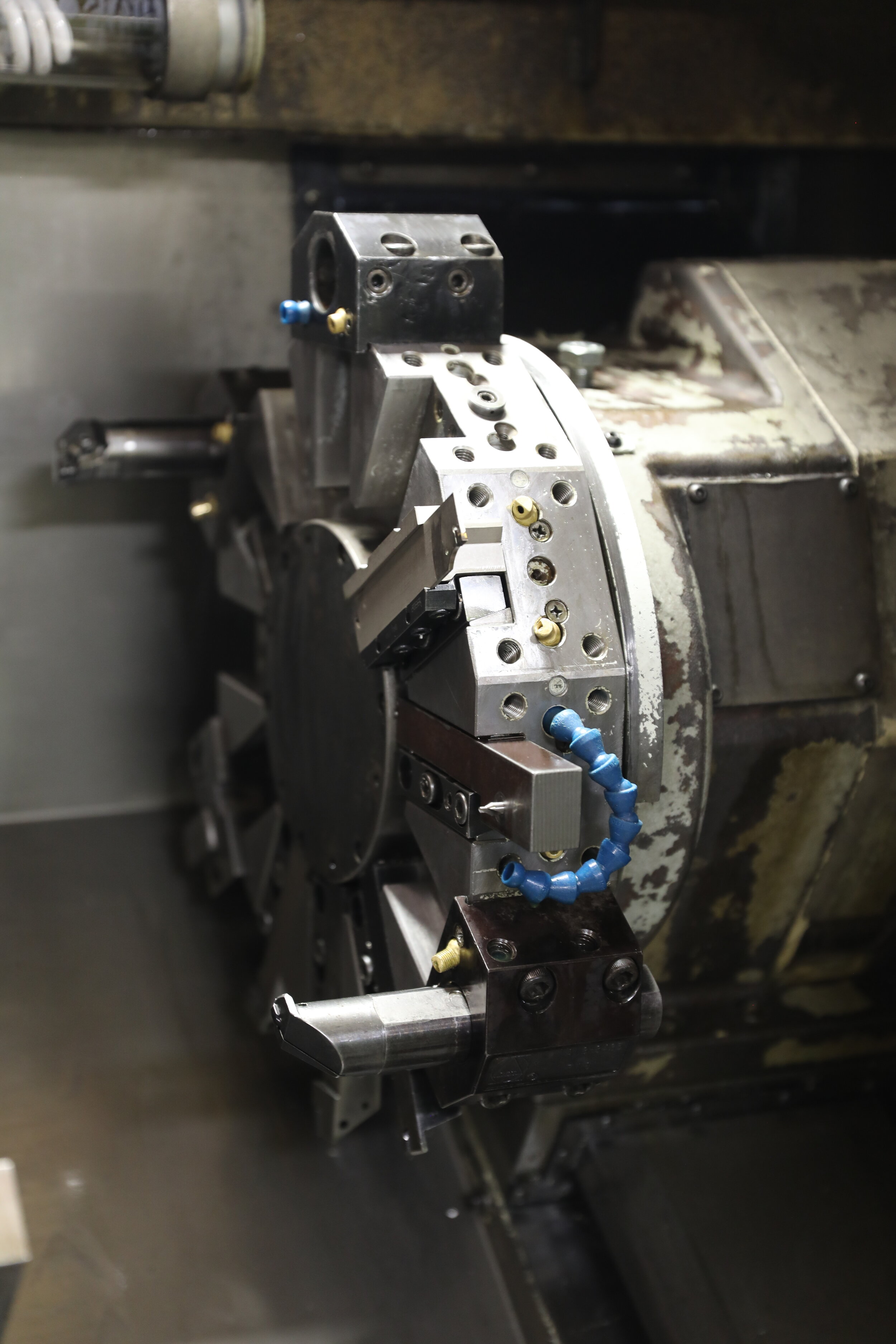

Precision Machining

Our 96 x 252-inch horizontal mill, one of the largest in the area available for job shop work, is capable of precision machining of very large parts. Meanwhile, our MA-40HA Horizontal Machining Center is equipped with automatic tool changers and chip removal with high-pressure throughout the tool coolant.

Powder Coating and Wet Paint

Martin Machine & Welding, Inc. provides the highest-quality powder coated finishes for our customers. When people think of powder coating, they usually think of basic black but at Martin Machine & Welding, Inc. we offer colors to fit your imagination. We can do custom color finishes as well as offer several high-quality black finishes from flat and textures to satins and high gloss.

MMW has designed and built an automated cleaning and powder coating line with drying and bake ovens. We stock an array of colors and can custom mix to get your own personal color.

Our 500-foot-long elevated spraying line is capable of extremely large production runs or one-off custom applications. Products are off loaded and carefully packaged for shipment to our customers.

Our capacity is 36” wide, 72” tall and 10’ long.

MMW boasts a 28’x80’x16’ wet paint facility. This standalone facility is climate controlled to allow year round finishing of your product.

Load Testing

MMW has engineered and built a one of a kind load test machine. With a work envelope of 30’ x 30’, we can accommodate very large weldments that need to be load tested up to 200 tons. “Stretch” has been an instrumental addition to MMW’s ability to serve oversized testing needs.

Additional Capabilities

Heat treat and stress relief (before and after welding), roll forming, brake forming, broaching, single point threading (internal and external) powder coating, blast cleaning, wet painting, and load testing up to 200 tons. In short, if it has to do with manufacturing, we do it at MMW.